PP Meltblown Vliesstoffmaschine

Holen Sie sich aktuelle Preis| Zahlungsart: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean |

| Hafen: | SHANTOU |

Select Language

| Zahlungsart: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean |

| Hafen: | SHANTOU |

Modell: SMF-RPM1600

Marke: SONNIG

| Verkaufseinheiten | : | Set/Sets |

| Pakettyp | : | SEEWERTIGES HOLZ ODER NACKT |

PP Meltblown Vliesstoff Modell SMF-RPM1600

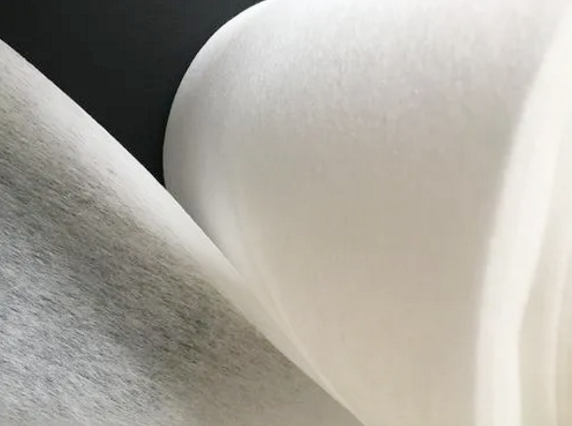

Anwendung: PP Meltblown Nonwoven Fabric Machine wird hauptsächlich zur Herstellung des Kernmaterials von Masken verwendet - PP Meltblown Nonwoven Fabric. Schmelzgeblasener Vliesstoff ist auch als "Herz" medizinischer Operationsmasken und N95-Masken bekannt. Es wird hauptsächlich in medizinischen Behandlungen, OP-Kleidern, Schutzkleidung, Desinfektionstüchern, Masken und Windeln verwendet.

Technische Parameter

1. Zum Schmelzen geblasenes Spinnharz: Polypropylen; Schmelzindex: 1200 bis 1800 g / 10 min; empfohlen: 1500 g / 10 min

2. Fertige Stoffbreite: 1600nn (Stoffbreite mit Graten: 1700mm)

3 Endgültige Gewebespezifikation: 15-80 g / m2

4 Schraubenspezifikation: Φ90 × 30

5 Sauggebläsekonfiguration: Durchfluss 20000 m3 / h, Volldruck 5000 Pa, Leistung 45 kW, Menge: 1 Satz

6 Heißluftheizleistung: 230KW

7 Konfiguration des Heißluft-Dehnungszuggebläses: Durchfluss 45 m3 / h, Luftdruck: 100 ~ 110 kPa

Maximale mechanische Geschwindigkeit: 80 m / min

Laufgeschwindigkeit: 8 ~ 60 m / min

8 DCD (Abstand zwischen Matrize und Kollektor): 100 ~ 350 mm

9. Installierte Leistung: ca. 750 kW

10 Werkstattanforderungen der Produktionslinie: L * B * H = ≥ 30 m × ≥ 16 m × ≥ 8 m

Produktanwendungsbereich :

Unternehmensvorstellung

1. Innovationsleiter für Forschung und Entwicklung Spezialisiert auf Design und Herstellung von Produktionslinien für atmungsaktive CPP / CPE-Folien, Produktionslinien für schmelzgeblasene Vliesstoffe, Extrusionslaminierbeschichtungsmaschinen und Primär- oder Sekundärschneider- und Aufwickelmaschinen in China seit 1998.

2. Hervorragender End-to-End-Service-Support. Zuverlässige Hilfe - auf der ganzen Welt

3. Immer zu Ihrer Verfügung. Unser spezielles Kundendienstteam bietet unseren Kunden zuverlässige Unterstützung, um den kontinuierlichen Betrieb der SUNNY-Maschinen jederzeit sicherzustellen.

4. Erfahrungen seit 1998

Service nach dem Verkauf

- Service ist unser Geschäft

- Telefonischer Support ohne Unterbrechung

- Fernbedienungswartungssystem

Kundenschulungsservice

- Gut ausgebildete und erfahrene SUNNY-Servicetechniker

- Innovatives Engineering und die Entwicklung helfen unseren Kunden, ihre Produktivität zu steigern.

Technischer Service Versprechen

- Bereitstellung mechanischer elektrischer, elektronischer und prozessbezogener Einstellungen.

- Analyse analysieren

- Immer für Sie entwickelt

- Immer speziell für Ihre Bedürfnisse optimiert

- Unser starkes Designteam kann auf umfangreiche Erfahrungen aus Hunderten von Linien zurückgreifen, die wir weltweit installiert haben

5. xpertise Abteilung für Maschinenbauingenieure, Montageabteilung, Abteilung für elektrische Automatisierung, Schulungsabteilung für Kundendienst und so weiter.

6. Es können erstklassige Maschinen bereitgestellt werden. Außerdem können alle Arten von Modifikationen nach kundenspezifischen Anforderungen angepasst werden.

Shantou Sunny Machinery Factory is an integrated professional manufacturer to produce, design and sell Slitting, Rewinding, Laminating, Coating, and CPP / CPE 3 or multiple layers Cast Film machinery facilities with more than 21 years of experiences. Over the years, we always set a motto of "science and technology as well as customer-centric products" that penetrated to the market quickly, obtained widespread and highly praised & trusted from new and existing clients. Our company has been developing and moving towards a greater competitive advantage by continuously improving technology and innovation. All project will be serviced by our expertise in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department , so we can offer our clients with our top standard machinery, also we can make all kinds of modifications according to customer specific requirements.

Currently, we have a team with highly-qualified professional and technical personnel and a well-experienced team to manufacture flexible package machine, they are the pinnacle of our factory. It is the foundation of our factory to occupy the market quickly. We will keep innovating continuously with excellent team perfecto create outstanding products of [SUNNY" brand. We aimed to be at the forefront in the industry and build creations that would enhance value for customers, create opportunities for staff and add benefits for the society.

Production models of professionalization, serialization, standardization have been formed. The 3 main product line have been created: 1. Rewinding, Slitting Machine Department; 2. Special Coating, Lamination Machine Department; 3. CPP / CPE three or multiple layers Casting Film Machine Department. Additionally , our machinery quality achieved ISO9001:2000 international quality management system certification and European Union CE certification. The total quality management and safety production management are improved and standardized continuously.

At present, 8 series products and more than 70 models machinery are formed as below:

1. High-speed wide range, plastic film etc one time slitting machine series;

2. High-speed paper, plastic etc two times slitting machine series;

3. Special slitting machine, inspection machine, rewinding machine series;

4. Golden silver paperboard coating, laminating, peeling and transferring machine series;

5. High-speed CPP, CPE 3 or multiple layers wide range Cast Film machine unit (1-6M) series;

6. High glossy photo cast glassine paperboard machine series;

7. Multiple layers co-extrusion cascade type extruding lamination machine unit (PE, PP, EVA) series;

8. UV 3D laser carving coating machine and embossing machine series;

Our machineries are sold in many countries including India, Indonesia, Thailand, Vietnam, Brazil, Poland, Korea, Italy, Philippines, Singapore, Russia, Malaysia, Pakistan and so on.

How we will do if you are interested to place order to us:

Once we get deposit, we will arrange purchase raw material immediately, and take photo for checking.

2. We will inform you the progress by pictures

3. What we are building, and which part is finalized, we will take picture and let you know.

4. When machine is ready, we will take complete machine pictures for you

5. When it is the delivery date, we will send email to you and let you know

6. After machine is loaded in container, we will take picture for your checking

7. After machine arrive at destination, and any problems occur, we will do our best to co-operate and support to solve all the problems.

We will make all step clearly and smoothly.

Why you choose us?

Safety production management and quality management

Production models of Professionalization, Serialization, Standardization.

17 years of advanced improvement and technological innovation, a very competitive advantage manufacturer.

Assembly Department, Mechanical Engineer Department, Electric Department, Software Department,

Special designed structure guaranteed the quality, steady, long life, performance

Professional pre-sales service

Products solutions

Factory solutions

Technische Lösung

Professional sales service

Project Information tracking

Technical support delivery

Survey feedback

Installation tracking

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-howsupport installation, debugging, operation of the machine as we will make sure you will know how to use this machine smoothly.

2.Clients Training Services

We can offer a training program your staff to use Machine equipment systems properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. We strongly believe the importance of supporting our customers and the product solutions we provided. Consequently,we offer comprehensive maintenance options to prevent any equipment damages before their life cycle. Also we offer one year guarantee period.

In a word, your satisfaction is our Forever Happiness!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.